Achieve Faster Time to Market

Moving into a data center has never been easier. If you value efficiency and convenience choose SharkRack to help with your rack integration. We have developed a reinforced cabinet capable of handling a 3,000 lb. dynamic load rating, that when paired with our unique packaging and shipping solutions, make the cabinets safe to ship fully loaded.

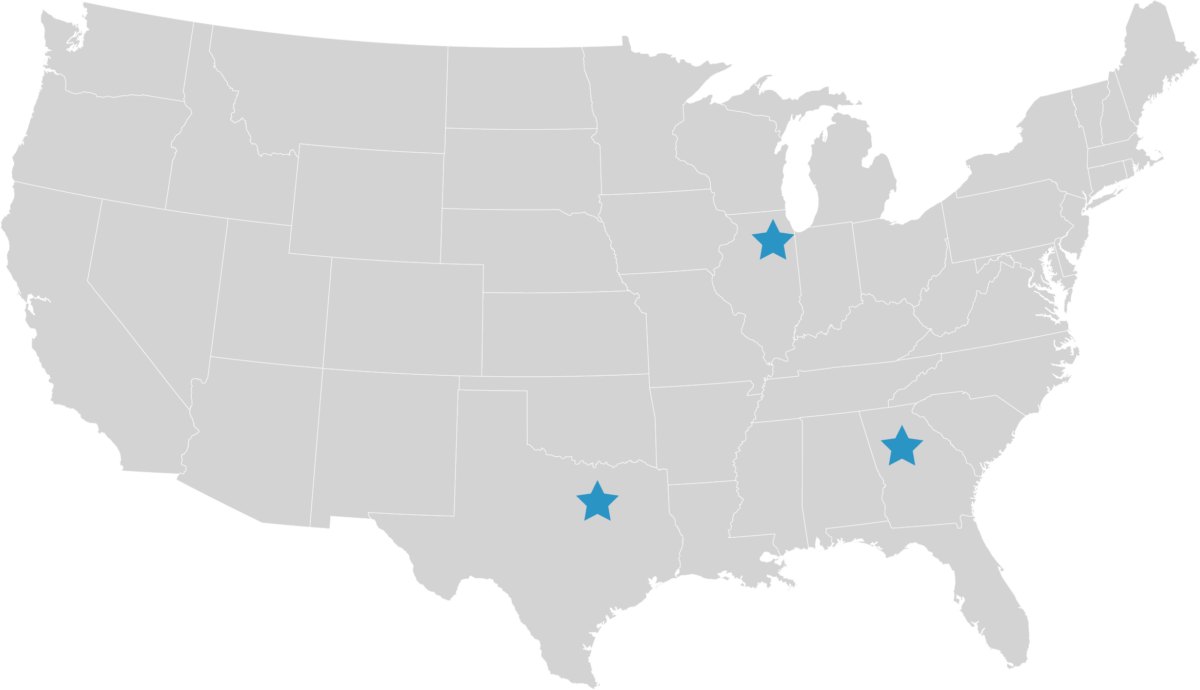

Multiple warehouses with stock.

With warehouses located across North America, we stock the most common size cabinets, and can deliver these Rack and Stack ready cabinets to an integrator quickly – and ultimately to the end user in as-shipped condition.

An extremely robust cabinet.

Perfect for Rack and Stack applications that require an extremely robust and durable enclosure. This cabinet offers a 3,000 dynamic load rating with an additional 20% of rear cable and PDU mounting space in 24” wide applications. Multiple sizes available – with the most common sizes in stock ready to ship.

- Locking front and rear doors with perforation for airflow.

- Horizontally split, locking, side panels make access easy.

- Vertical cable/PDU managers (two) included.

- Square hole mounting rails are adjustable front to rear.

- Rear doors are split “frech style” to save aisle space.

- Grounding kit and baying hardware included.

- Levelers and heavy duty casters come standard.

- Full range of optional accessories.

Custom designed wood crates.

Sensitive electronics should be shipped in a wood crate. Custom-designed wood crates offer maximum protection for fragile items. They may be crafted for a single use or, if you ship a particular type of item regularly, they can be designed to be reusable.

Special pallets.

A floating deck is a base that is designed to absorb the shock and energy a crate receives during shipping. Floating decks can allow for various types of movement during transport: front-to-back, side-to-side, and up-and-down movement.

Shock and tip sensors.

These devices detect different types of forces affecting a shipping container or changes in its position so that you know whether it endured any concerning stresses during its travels.

Optional anti-static protection.

In some cases, an electronic item isn’t damaged by things like being bounced around while in transit, but rather by a buildup of static electricity that subsequently damages its circuits or other components. Anti-static wrap can keep that buildup from occurring.

Ramps for loading and unloading.

Moving an item into or out of a container without caution can lead to damage. Any transitions an item will make should

be conducted carefully and smoothly, using a ramp or other assistive equipment as needed.

Help with logistics.

We have access to dedicated shipping companies avoiding hubs, and instead, shipped directly from our facility to yours.

Stop tying up valuable IT resources.

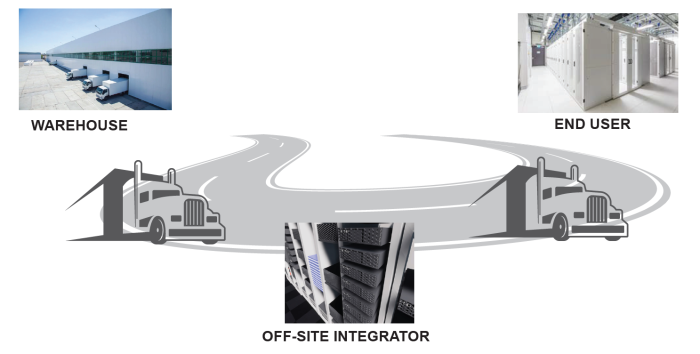

It might seem cheaper and easier to perform the rack integration in-house, however, there are downsides. Few organizations have adequate lab and storage space for a large rack and stack project. The process also distracts the IT team from the day-to-day management of the data center. Rack integration and rack and stack services eliminate these headaches.

OPTION 1. USE YOUR OWN INTEGRATOR

Our robust cabinet is packaged in a specially designed crate and transported to the integrator. The Integrator installs and tests the equipment. The cabinet is re-packed in that same specially designed crate. The fully (racked) cabinet is then shipped to the end user for deployment (stacked).

OPTION 2. UTILIZE OUR RACK INTEGRATION SERVICES

Same as above, but instead of shipping to an off-site integrator, we provide the integration service. We have the expertise and space to handle the rack integration from end to end.

Innovation

Innovation is the driving force at Enconnex. When customers have problems, we build solutions.

Innovation

Innovation is the driving force at Enconnex. When customers have problems, we build solutions.

Innovation

Innovation is the driving force at Enconnex. When customers have problems, we build solutions.